ASCII Ethernet TCP/IP to Allen-Bradley PLC

The fastest and simplest way to move ASCII Ethernet TCP/IP barcode, weighscale, and RFID data to Allen-Bradley PLCs

490NBX

$NZD 1,369.15 - $NZD 1,489.58

Please note, site orders are made via credit card. Please contact sales@techstep.co.nz if you require support to purchase directly.

Product Description

Moving Ethernet TCP/IP to a PLC Made Easy

There are a ton of perfectly good scales, barcode readers, printers and display devices that communicate with TCP data. This is equipment that you’ve used for a long time. You know how to set it up, how to make it work and that it’s reliable.

The problem is that you still have to connect these devices into your Allen-Bradley PLC. That means writing and testing PLC logic. Not hard – just another task to do and more code to support. But there is a better way, a much better way. If you could move the data right into the PLC’s registers, it would save you time, money and a pile of headaches

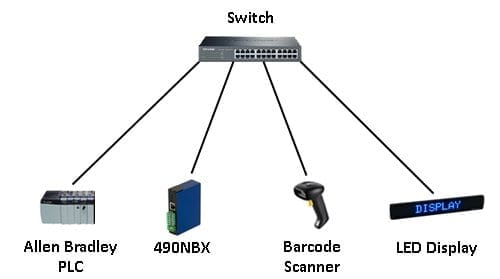

That’s the device we have developed for you. It quickly and easily moves barcode data, weigh scale data and other TCP device data to Allen-Bradley PLCs. The 490NBX moves your raw TCP data to a PLC with little or no delay. Milliseconds after receiving your raw TCP data, it is transferred to your user-specified tag in the PLC. Simply configure the input data format, the IP address of the PLC and a PLC tag using a very simple browser interface and you are ready to run. No standalone or custom software is required. It’s that simple.

How it Works

You don’t need to use message instructions to move data into a PLC. We have found a simpler way to send the data. You define a tag in the PLC for our unit to monitor. Our unit watches the string length and anytime it sees a non-zero value we send that data and set the string length back to zero.

Whenever we see data in our unit from your device, we send it out to a tag in the PLC. On the TCP device side, we transfer raw TCP data. Our unit can connect to your device by imputing the device’s IP address or it can wait for the device to connect to it by leaving the address 0.0.0.0.

Is It Really that Easy to Use?

Yes, these units are so popular because they are so easy to set up. There is no software to download or code to write. You simply map the tags to monitor and set your device’s connection and you are done. This is all done via a built-in browser-based interface. You pull up the webpage and enter your configuration. The whole thing can be set up in less than ten minutes.

- Manual

- Power cable with flying leads

- 5-Year hardware warranty

- IPSetup software — automatically locates RTA gateway on the network

- Unlimited firmware feature upgrades for life

- CAT5 cross over cable for direct connection to PC during programming

- Complete, unlimited access to our industry leading support staff

ASCII Features

Maximum Number of ASCII devices: 10Wide Characters: Add Padding on Outgoing

Communications: EtherNet TCP/IP

Message Queue Size: Configurable, 0-20 messages

Ethernet/IP Tag Client Features

PLC Support

ControlLogix, CompactLogix, FlexLogix, MicroLogix, SLC’s and PLC5E’s

Maximum Number of PLCs Supported

1

Messaging Operation

Connected or Unconnected

Net ENI Support

Supported

Gateway Security

You can configure a user with access to diagnostic and configuration screens.

Status and Counters

Protocol-specific status, counters and error messages are accessible within the gateway's diagnostics page.

Diagnostic Logging Page

Allows users to see and log start up sequences, protocol-specific messages and error messages.